Double-Sided Flexible Circuits (FPC) – 2-Layer Plated-Through-Hole Flexible PCB for Wi-Fi Antennas and More

(Printed Circuit Boards are custom-made products, the picture and parameters shown are just for reference)

In the fast-paced world of electronics, flexibility and reliability are essential for designing compact and efficient devices. The Double-Sided Flexible Circuits (FPC) is a high-performance solution designed for applications requiring flexibility, reduced weight, and space-saving designs. Built on SF305 Adhesive Polyimide at 0.15mm thick, this 2-layer FPC is ideal for Wi-Fi antennas, keypads, and other compact electronic applications.

Key Features of Double-Sided FPC

1.Excellent Flexibility: The FPC can be freely bent, wound, and folded, making it ideal for applications where space and flexibility are critical.

2.Reduced Volume and Weight: By using FPC, the overall volume and weight of electronic products can be significantly reduced, enabling the development of smaller and lighter devices.

3.Plated-Through-Hole (PTH) Technology: The double-sided FPC features plated-through holes, ensuring reliable electrical connections between layers.

4.Immersion Gold Surface Finish: The immersion gold finish on the pads provides excellent conductivity, corrosion resistance, and solderability, ensuring ong-term reliability.

5.No Minimum Order Quantity (MOQ): We offer low-cost samples and no MOQ, making it easier for you to test and integrate the FPC into your designs.

6.High Reliability: The FPC is manufactured to IPC 6012 Class 2 standards, ensuring high quality and reliability.

7.Volume Production Capability: With the ability to produce 8,000 types of PCBs per month, we can handle both small and large-scale orders efficiently.

.jpg)

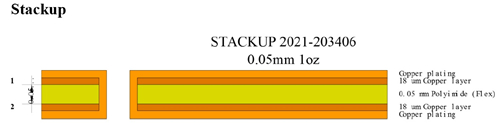

FPC Specifications

| Number of Layers | Double sided |

| Outline Dimension | 21.15 x 58.93mm = 1PCS |

| Board Type | Flexible Circuit |

| Board Thickness | 0.15mm +/-10% |

| Board Material | Polyimide (PI) 50 um |

| Board Material Supplier | Shengyi |

| Tg Value of Board Material | 60℃ |

| PTH Cu thickness | ≥20 um |

| Inner Iayer Cu thicknes | N/A |

| Surface Cu thickness | 35 um (1oz) |

| Coverlay Colour | Yellow |

| Number of Coverlay | 2 |

| Thickness of Coverlay | 25 um |

| Stiffener | 200 um |

| Type of Silkscreen Ink | IJR-4000 MW300 |

| Supplier of Silkscreen | TAIYO |

| Color of Silkscreen | White |

| Number of Silkscreen | 1 |

| Mininum Trace (mil) | 4 mil |

| Minimum Gap(mil) | 4 mil |

| Surface Finish | Immersion Gold |

| RoHS Required | Yes |

| Famability | 94-V0 |

| Thermal Shock Test | Pass, -25℃±125℃, 1000 cycles. |

| Thermal Stress | Pass, 300±5℃,10 seconds, 3 cycles. No delamination, no blistering. |

| Function | 100% Pass electrical test |

| Workmanship | Compliance with IPC-A-600H & IPC-6013C Class 2 |

Applications

The Double-Sided FPC is well-suited for a variety of applications, including:

Wi-Fi Antennas: Ideal for compact and lightweight designs in wireless communication devices.

Keypad FPC: Ensures reliable performance in mobile phone keypads and other input devices.

Toy Lamp Strips: Suitable for flexible lighting applications in toys and decorative items.

Display Backlight: Perfect for backlighting in LCD and LED displays.

POS Antenna Soft Boards: Ensures stable performance in point-of-sale systems.

LCD TV Soft Boards: Ideal for flexible connections in television displays.

Digital Camera Soft Boards: Suitable for compact and flexible designs in camera systems.

.jpg)

Why Choose Double-Sided FPC?

1.Versatility: The FPC can be used in a wide range of applications, from consumer electronics to industrial devices.

2.Cost-Effective: The FPC offers a low-cost alternative to traditional rigid PCBs, making it an economical choice for high-volume production.

3.High Reliability: The FPC is manufactured to IPC 6012 Class 2 standards, ensuring high quality and reliability.

4.Global Availability: Ready to ship worldwide, ensuring timely delivery for your projects.

Parameters (SF305)

| Test Item | Test Method | Unit | IPC Standard |

Typical Value | |

| SF305 051813DR |

SF305 051813SE |

||||

| Peel Strength 90° | IPC-TM-650,No.2.4.9 Method A Method C |

N/mm | ≥0.7 ≥0.525 |

1.1 1.0 |

1.3 1.2 |

| Thermal Stress | IPC-TM-650,No.2.4.13 | - | Pass | Pass | |

| Dimensional Stability | IPC-TM-650,No.2.2.4 Method B |

% | ±0.15 | MD: -0.0684 TD: 0.0691 |

MD: -0.0418 TD: 0.0354 |

| Chemical Resistance | IPC-TM-650,No.2.3.2 | % | ≥80 | >85 | >85 |

| Moisture Absorption | IPC-TM-650,No.2.6.2 | % | ≤4 | 1.46 | 1.37 |

| Volume Resistivity | IPC-TM-650,No.2.5.17 | MΩ-cm | ≥10^6 | 1.5×10^8 | 2.0×10^8 |

| Surface Resistance | IPC-TM-650,No.2.5.17 | MΩ | ≥10^5 | 5.0×10^6 | 4.5×10^6 |

| Dielectric Constant 10GHZ | IEC-61189-2-721 | - | - | 3.34 | 3.31 |

| Dissipation Factor 10GHZ | IEC-61189-2-721 | - | - | 0.0191 | 0.0188 |

| Dielectric Strength | IPC-TM-650,No.2.5.6.1 | V/μm | ≥80 | 134 | 140 |

| Folding Endurance (MIT method) | R0.38×4.9N,with cvl | Times | - | >2000 | >1000 |

Double-Sided Flexible Circuits

As the name implies, the circuit is made up of a thin, flexible base material with copper foil laminated on both sides. The outer layers of the finished circuits are often covered with protective coverlays bonded to the copper surfaces. In double-sided flexible circuits, plated-through holes are typically drilled rather than punched. Additionally, these flexible circuits usually come with coverlays applied to both sides for enhanced protection and durability.

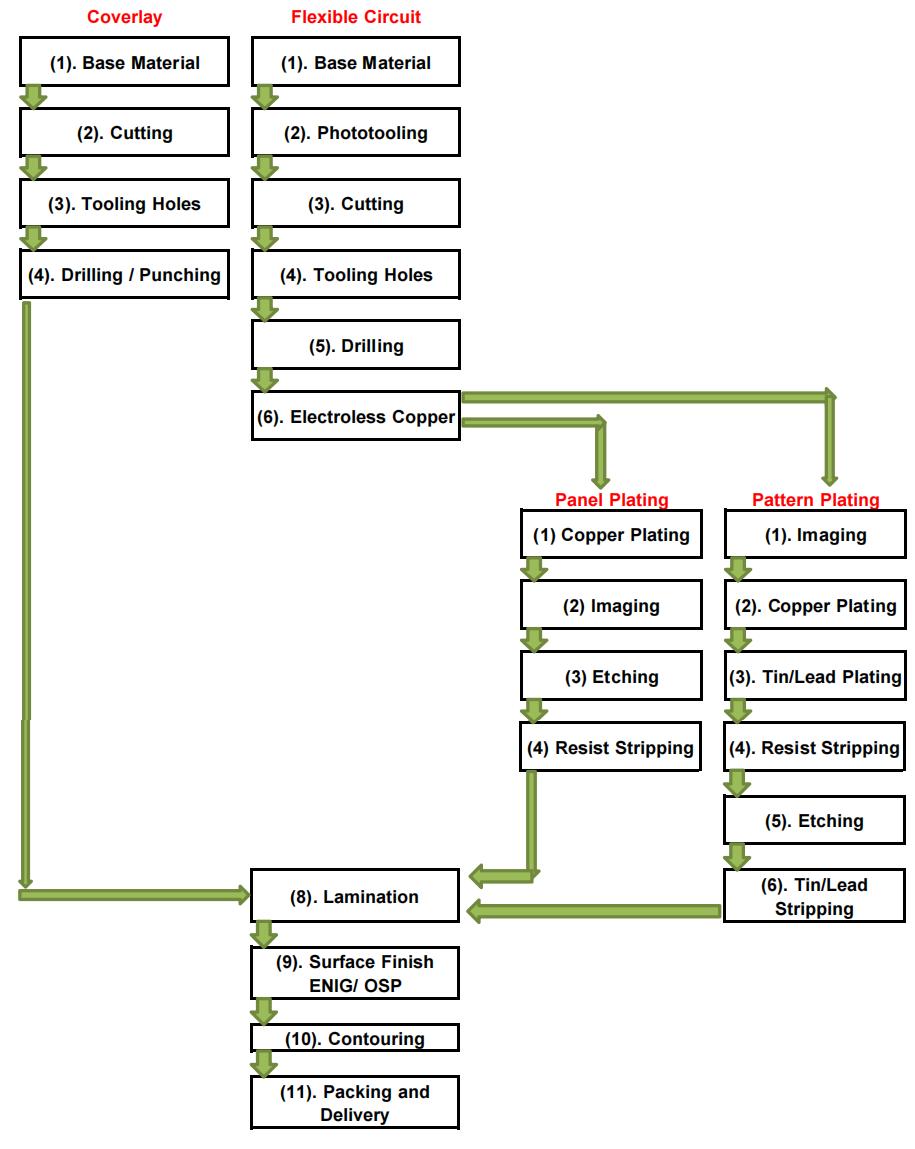

Manufacturing Process of Double Sided FPC

Although manufacture of double-sided PTH flexible PCB resembles that of single-sided non-plated-through boards, some of the manufacturing processes are not identical and appear in another sequence. Below it shows the processes of how to manufacture a double sided flexible circuits.

Conclusion

The Double-Sided Flexible Circuits (FPC) is a high-performance, cost-effective solution designed for applications requiring flexibility, reduced weight, and compact designs. With its excellent flexibility, high reliability, and low cost, it is an ideal choice for engineers working on Wi-Fi antennas, keypads, display backlights, and more.

Whether you're designing for consumer electronics or specialized industrial applications, the Double-Sided FPC offers the reliability and performance you need to bring your projects to life.

.jpg)

.jpg)